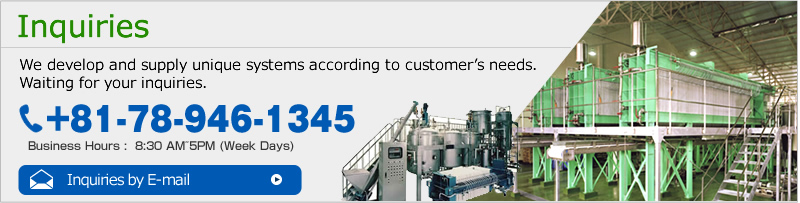

Yabuta Filter Press Model 66 & 100

Yabuta Automatic Filter Cake Scraping System

- Special Features

- Type 66 and type 100 models are the simple machine capable of use in a broad range of fields.

- The pressure plate and filter plate, which come in contact with the liquid solutions, are composed of stainless steel, FRP, Aluminum, or PP (Polypropylene).

- Operation methods are manual, semi-automatic, and fully automatic. Automatic cloths washing system can be attached.

- There are two types of structures: filter cake without frames (DN Type), and the filter cake with frames (D, FR Types).

- High quality filtration takes place.

- The filter press is applied before the Ultra Filtration Membranes Process.

STANDARD MODEL SPECIFICATIONS

| Model | Chambers | Plate Size (mm) |

Filtration Area (m²) |

Filtration Capacity (m³) |

Electric Power (kw) |

|---|---|---|---|---|---|

| FR66 66D 66DN |

6-40 | 660x660 | 4-28 | 0.05-0.36 | 0.8-2.7 |

| 100D 100DN |

10-100 | 1000x1000 | 17-170 | 0.25-2.50 | 1.9-16.05 |

| 100DN II | 4 | 1000x1000 | 6.8 | 0.10 | 1.5 |

- OPTIONS

- Control Panel (manual, semi-automatic, and fully automatic)

- Automatic Plate Shifter

- Automatic Filter Cloths Washing System

- Sanitary Specifications

- Pre-coating Instrument

- Stainless Steel Mainframe Lining

- Filter Cake Removal Conveyor and Stage

- Design and Construction Pre-Filtering and Post-Filtering Machines

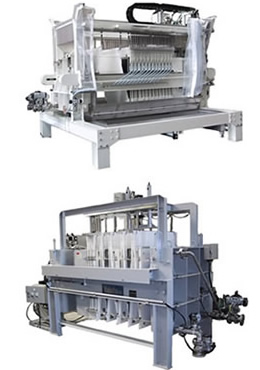

Yabuta Full Automatic Filter Press TypeⅡ

The type Ⅱ filter press is a fully automatic system equipped with an automatic cake removal function and filter cloth washing function, eliminates the manual labor and energy consumption.

- SPECIAL FEATURES

- The TypeⅡ filter press is fully automatic system equipped with an automatic filter cake removal function and an automatic filter cloths washing function.

- The filtration processing time is short and the cycle is various.

- Many systems have been well received in production, waste water, and pollution control.

- A filter cake removal conveyor, stage, a drip pan, and so on are available as an option.

- The TypeⅡ filter press allows for reduction of the manufacturing cost and improve the labor environment.

STANDARD MODEL SPECIFICATIONS

| Model | Chambers | Plate Size (mm) |

Filtration Area (m²) |

Filtration Capacity (m³) |

Electric Power(kw) | |||

|---|---|---|---|---|---|---|---|---|

| hydraulic closure | compressed air | plate shifter | cloth washing | |||||

| 100YAFII 135YAFII |

10~100 | 1000×1000 | 17~170 | 0.25~2.50 | 0.75 | 2.2~5.5 | 0.4 | 11~15 |

| 1350×1350 | 32~320 | 0.45~4.50 | 2.2 | |||||

| 100DNII | 4~8 | 1000×1000 | 6.8~13.6 | 0.1~0.2 | 0.75 | 0.75 | - | - |

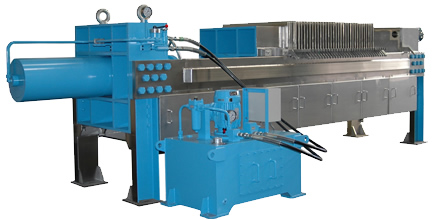

High Feeding Pressure Filtration Press

This system is a High Feeding Pressure Filtration Press to be able to filtrate high viscosity slurry.

The plate structure is the type of plates and frames, can exchange filter easily.

Jacket type plate is available for high temperature filtration.

- SPECIAL FEATURES

- This system is a High Feeding Pressure Filtration Press to be able to filtrate high viscosity slurry.

- The maximum operation feeding pressure is 2,000 kPaG.

- The plate structure is the type of filter cakes with frames.

- Operation methods are manual, semi-automatic, and fully automatic.

- High quality filtration takes place.

- The filter press is applied before the Ultra Filtration Membranes process.

- OPTIONS

- Control panel (manual, semi-automatic, and fully automatic)

- Automatic Plate Shifter

- Automatic Cake Washing System

- Stainless Steel Mainframe Lining

- Filter Cake Removal Conveyor and Stage

- Design and Construction Pre-Filtering and Post-filtering Machines

STANDARD MODEL SPECIFICATIONS

| Model | Chambers | Plate Size (mm) |

Filtration Area (m²) |

Filtration Capacity (m³) |

Electric Power (kw) |

|---|---|---|---|---|---|

| 100SQ | 10-46 | 1000x1000 | 16-75 | 0.20-0.90 | 3.7 |

Compact Filter Press for Research

Filtration test, sample creation, ideal compact model compressed air system filter press for actual model selection.

- SPECIAL FEATURES

- A mobile and easy to use unit, ideal for research room use.

- Because of High purification level of filtered liquid, the filter press can be applied before the Ultra Filtration Membranes Process.

- Small scale filter press model equipped with a compressed air system which produces a low moisture cake or better cake retains a high level of filtered liquid.

- Depending on the liquid, various machine materials may be selected for use.

- High pressure at a maximum 6MPa squeezing presses which use water pressure are available.

STANDARD MODEL SPECIFICATIONS

| Model | Chambers | Filtration Area (m²) |

|---|---|---|

| M O Model | 2~4 | 0.09~0.18 |

| 40 D Model | 2~10 | 0.44~2.19 |

| 50 D Model | 2~10 | 0.73~3.66 |