Vacuum Distilling (Concentrating) System

This Vacuum Distilling System, compared with the former Non-Vacuum Distillation Systems produces an extremely soft tasting and pleasant smelling distilled alcohol.

- SPECIAL FEATURES

- Distillation occurs at a low temperatures which produces fine product.

- Many types of products can be distilled by inverter controlled vacuum pump.

- Plate type condenser, and plate type cooler which allow for the machine to operate with very little cooling water. The cooling tower is also able to be used in the large scale model.

- Large scale model consists of 1 product tank which can continuously remove products during the distillation process.

- Alcohol meter, sample cock, thermometer, and pressure gauge, allow for operating conditions to be overseen with one look.

- An atmospheric pressure and vacuum pressure compatible model is available. Models with capacities 6000L and above are available.

STANDARD MODEL SPECIFICATIONS

| Specification Model | Condenser | Cooler | Product Tank |

|---|---|---|---|

| 750 | Plate | Plate | 1(separated) |

| 1000 | Plate | Plate | 1(separated) |

| 1500 | Plate | Plate | 1(separated) |

| 2000 | Plate | Plate | 1(separated) |

| 3000 | Plate | Plate | 1(separated) |

| 4000 | Plate | Plate | 1(Continuous removal) |

| 5000 | Plate | Plate | 1 (Continuous removal) |

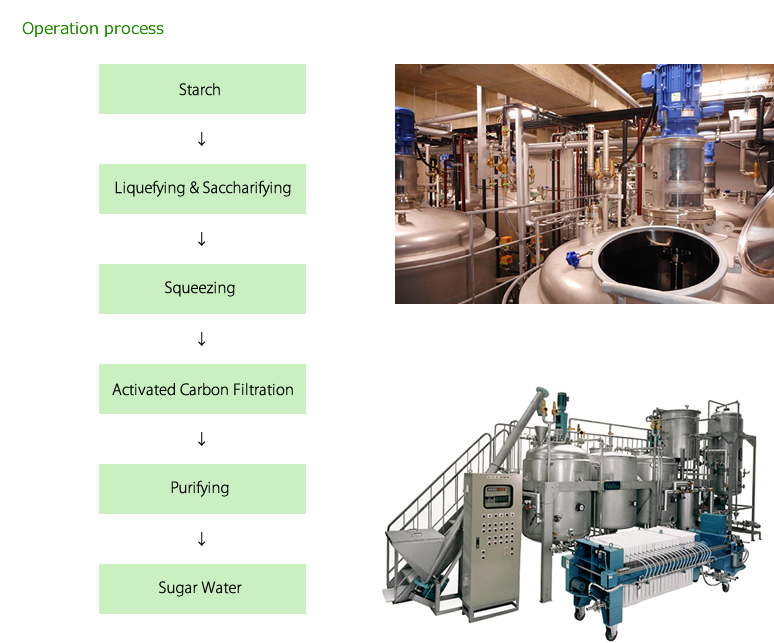

Liquefy, Saccharifying & Amazake Production System

Starch saccharifying technique with malt, koji and/or enzyme in the fermentation process and so on is well received in many manufacturing fields such as Japanese Sake, Shochu, Amazake, Vinegar, Sauce and Confectionery.

YABUTA has various experiences of saccharifying, liquefying & saccharifying, Yodan fermentation tank. Our basic technologies of material input, agitation and temperature control in Amazake production receive high evaluation.

- SPECIAL FEATURES

- This system allows the manufactured bran to become a more suitable ingredient for Japanese Sake and other foods.

- The system allows the products to become smooth and light taste by using the high purity saccharified water.

- Various enzymes are used to create a range of sugar water solutions. This broad range of available solutions allows easier control over the taste of products.

- This system is applied to liquefying process of crashed rice and normal rice.

STANDARD MODEL SPECIFICATIONS

| Model | Sugar Water Amount (25%L) |

Installation Area (m×m) |

Used Steam Amount (TON) |

Used Water Amount (TON) |

Electric Power (kwh) |

|---|---|---|---|---|---|

| 600 kg Type | 1500 L | 8×8 | 0.7 | 10 | 13 |

| 1000 kg Type | 2500 L | 8×9 | 1.1 | 16 | 16 |

| 1500 kg Type | 3700 L | 10×10 | 1.6 | 24 | 20 |

| 2000 kg Type | 5000 L | 10×12 | 2.1 | 30 | 23 |

| 3000 kg Type | 7500 L | 10×16 | 2.9 | 48 | 28 |

| 4000 kg Type | 10000 L | 10×20 | 3.8 | 60 | 32 |

| 6000 kg Type | 15000 L | 11×25 | 5.5 | 95 | 40 |

Rice liquefying System

In the types of liquefying fermentation of Japanese Sake & Shochu, not only crashed but whole rice is available in this system. YABUTA has special technologies as for temperature, agitation control and recipes.

- SPECIAL FEATURES

- Both powder and non-crashed rice are able to liquefy with this system.

- Small scale system adopts batch operation, and large scale system adopts continuous operation respectively.

- In case of continuous operation, materials are crashed by special pump and liquefied by high temperature in-line injection apparatus.

- Many processes are automatically operated, such as water input, material supply, enzyme addition, liquefying, and cooling process.

Non-air Circulation Koji Manufacturing System

Yabuta Non-air Circulation Koji Manufacturing System consists of culture dish trays surrounded by an upper and lower flat tank which utilize warm water for temperature control.

The absence of circulating air prevents oxidation and allows the Koji homogeneous & high quality.

- SPECIAL FEATURES

- The culture tray is temperature controlled and air circulation is unnecessary, so that the oxidation and air short-pass are prevented.

Utilizing high quality heat transmissible aluminum culture trays, the warm water contained in the upper and lower frat tanks control the temperature. During Koji Cultivation the absence of circulating air allows the Koji resulting from Kojibuta to be manufactured. - Architectural design based on operational efficiency.

Supplying, Stirring, Carrying Out and Quality Check are easily accomplished.

The structure of the aluminum culture trays and mainframe allow for easy cleaning. This system is capable of being placed inside the Koji manufacturing room. Teflon coating of culture trays is available. The supplying process is automatically processed by the adaptation of the loading cell. - From the supplying to carrying out stages, the Koji remains in its original culture trays.

High quality Koji is manufactured.

Because the Koji remains in its original culture trays from the supplying to carrying out stages, the system structure is simple and the running cost is low.

Temperature control is easily accomplished due to the slim line structure of the culture tray (approx. 5cm thick). - The full automatic control system was developed based on the traditional manufacturing process parameters.

This original system brings about the reappearance of traditional tastes and aromas.

The easy to use touch panel type control panel can easily program the temperature and humidity.

STANDARD MODEL SPECIFICATIONS

| Koji Weight (kg) |

Width (mm) |

Length (mm) |

Height (mm) |

Electric Power (kw) |

Weight (kg) |

|---|---|---|---|---|---|

| 300 | 6000 | 8500 | 2700 | 10 | 4000 |

| 500 | 6000 | 10000 | 2700 | 10 | 4500 |

| 600 | 6000 | 8500 | 3200 | 10 | 5000 |

| 800 | 6000 | 9300 | 3200 | 10 | 7000 |

| 1000 | 6000 | 10000 | 3200 | 10 | 8000 |

| 1500 | 6000 | 12600 | 3200 | 13 | 9000 |

| 2000 | 6000 | 14200 | 3200 | 15 | 10000 |